Slip Casting Process For Ceramics Pdf

Slip casting is the process of filling the molds with slip which is the liquid clay allowing it to solidify and after a while forming a layer called the cast inside of the mold s walls.

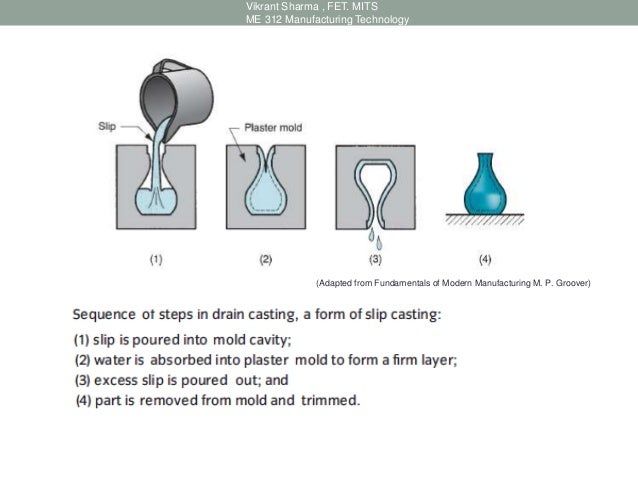

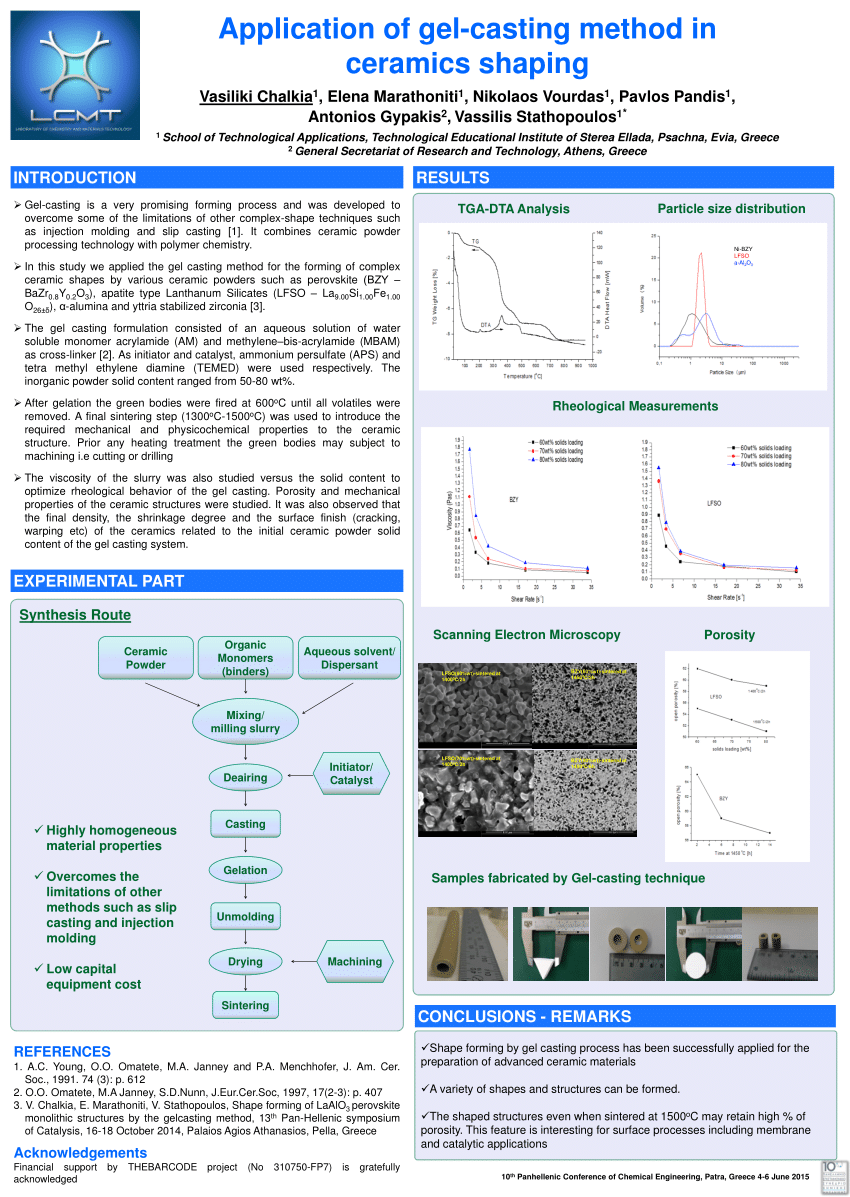

Slip casting process for ceramics pdf. Reducing the time for sinter ing reducing temperature of sintering slip casting clay product a slip is a suspension of clay and or other nonplastic materials in water. Schematic showing the steps used in slip casting. First the slip is prepared by mixing the ceramic powder with a liquid. The slip casting process slip casting is the process of filling a porous mould 1 usually a gypsum mold with a ceramic slurry 3.

Schematic showing the steps used in slip casting. The slip casting process is illustrated below in figure 1. The water is removed from the slurry via capillary action through the small pores in the mold 4. As the water is removed the slurry the ceramic particles are collected against the surface of the mold.

This happens because the mold absorbs the water from the slip through its pores collecting the ceramic particles against the mold. The slip casting process is illustrated below in figure 1. These products can be used for industrial. Next the slip is poured into the mold which absorbs the liquid out of the slip leaving a thin wall of powder along the mold wall.

Next the slip is poured into the mold which absorbs the liquid out of the slip leaving a thin wall of powder along the mold wall. Slipcasting or slip casting is a ceramic forming technique for pottery and other ceramics especially for shapes not easily made on a wheel. A slip casting process with demolding of the outer mold and firing of the mold core see figure 5 31 was used to prepare a porous α al 2 o 3 ceramic tube with inner diameter of 7 mm wall thickness of 1 5 mm length of 20 cm average pore size of 1 μm and porosity of 43 created by sintering 52. This demonstration or labprovides an introduction to the slip casting method and how basic ceramic parts canbe created it also provides.

The water is removed from the slurry via capillary action through the small pores in the mold. First the slip is prepared by mixing the ceramic powder with a liquid. The slip casting process slip casting is the process of filling a porous mold usually a gypsum mold with a ceramic slurry. In slipcasting a liquid clay body slip usually mixed in a blunger is poured into plaster moulds and allowed to form a layer the cast on the inside walls of the mould.

There are many forming techniques to make ceramics but one example is slipcasting this is where slip or liquid clay is poured into a plaster mould.