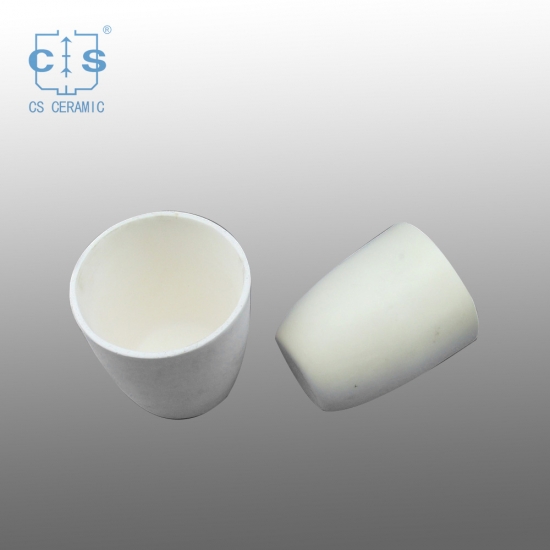

Slip Casting Alumina Ceramics

Slip casting is the process of filling the molds with slip which is the liquid clay allowing it to solidify and after a while forming a layer called the cast inside of the mold s walls.

Slip casting alumina ceramics. Rajnish kumar jain challapalli subrahmanyam toxic free aqueous gelcasting of alumina ceramics using alumina sol binder international journal of applied ceramic technology 10. The slip casting process is illustrated below in figure 1. As the liquid filters into the mould a cast is formed on the mould surface. Slip casting the most traditional of these is easy to operate and it is applicable to creating complex shaped products but difficult to apply to the production of hollow thin walled highly pure porous alumina.

Pröbster l 1 diehl j. Historically ceramic materials in the form of clay figurines and pots were the first man made materials over 10 000 years ago and maybe even as long as 25 000. Slip casting is a process used to consolidate ceramic powders into sophisticated shapes with high green densities. Slip casting refers to the filling of a mould a negative of the desired shape with a slip consisting of a suspension of micrometer size ceramic particles in liquid.

1 university of tübingen dental school germany. Schematic showing the steps used in slip casting. Slip casting of aluminum oxide w. Students will learn the fundamentals of slip casting and be able to think critically about why slip casting is used.

Division of ceramics department of metallurgy massachusetts institute of technology cambridge 39 massachusetts. This happens because the mold absorbs the water from the slip through its pores collecting the ceramic particles against the mold. The capillary action due to the pores in the mould withdraws the liquid from the slip. First the slip is prepared by mixing the ceramic powder with a liquid.

Bags that require mixing with water and a deflocculant such as soda ash sodium silicate darvan 7 or darvan 811. The common methods for molding porous ceramic carriers are slip casting pressure forming and plastic extrusion forming 108. Currently it is used mainly for the production of large components or for those having thin walls or a shell of complicated contours where the costs involved preclude the use of other techniques such as die pressing or isostatic pressing. Liquid casting slips are available in low fire midrange stoneware high fire stoneware and porcelain.

This is to certify that the project entitled preparation of dense alumina ceramic by slip casting method submitted by rahul anand roll no. Next the slip is poured into the mold which absorbs the liquid out of the slip leaving a thin wall of powder along the mold wall. We also have dry mix casting slips available in 50 lb. Casting slips are pre made ready to use for pouring and making casts in plaster molds.

1 teacher instructions ceramic processing.