Shop Floor Dashboards

Visibility from your shop floor throughout your organization using our browser based management dashboard or api integration back to erp.

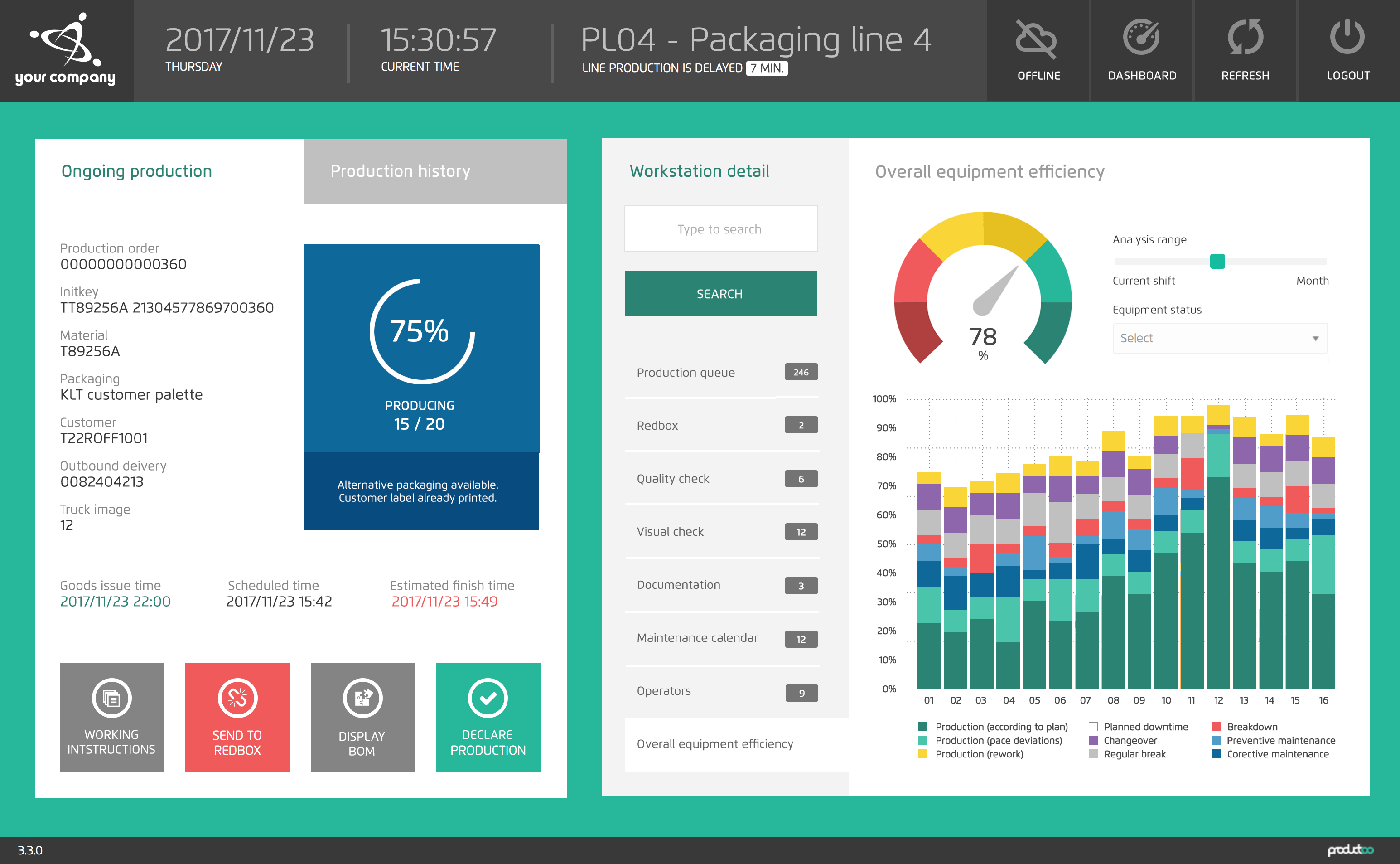

Shop floor dashboards. Ship orders or put them on hold. Our dashboards for manufacturers put data and functionality in one screen so you can perform nearly all of your job functions without changing screens. Save time by replacing analog manual shop floor dashboards with digital ones. View our fact sheet here.

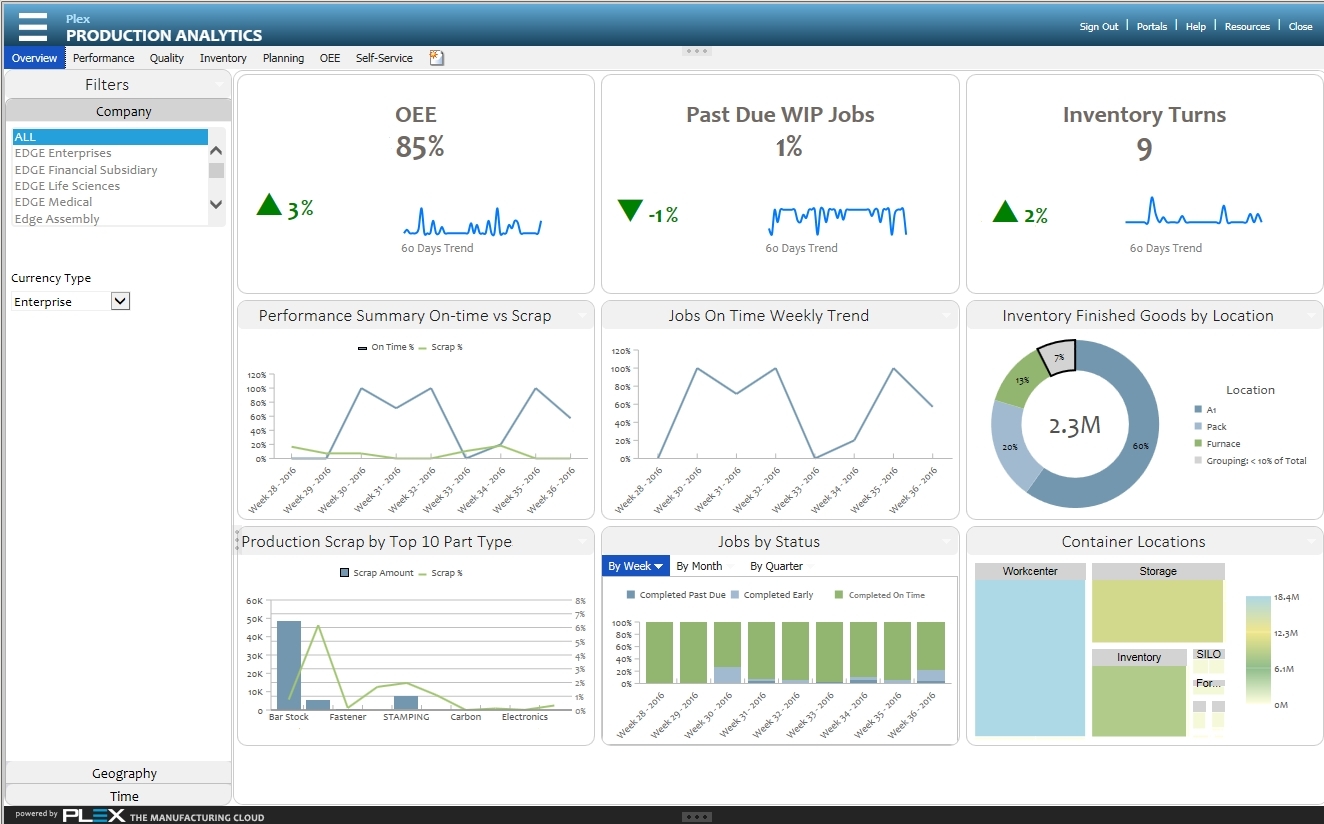

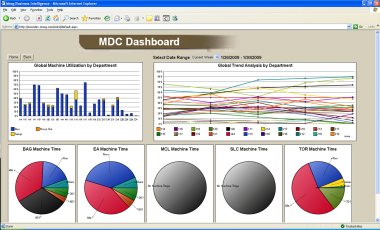

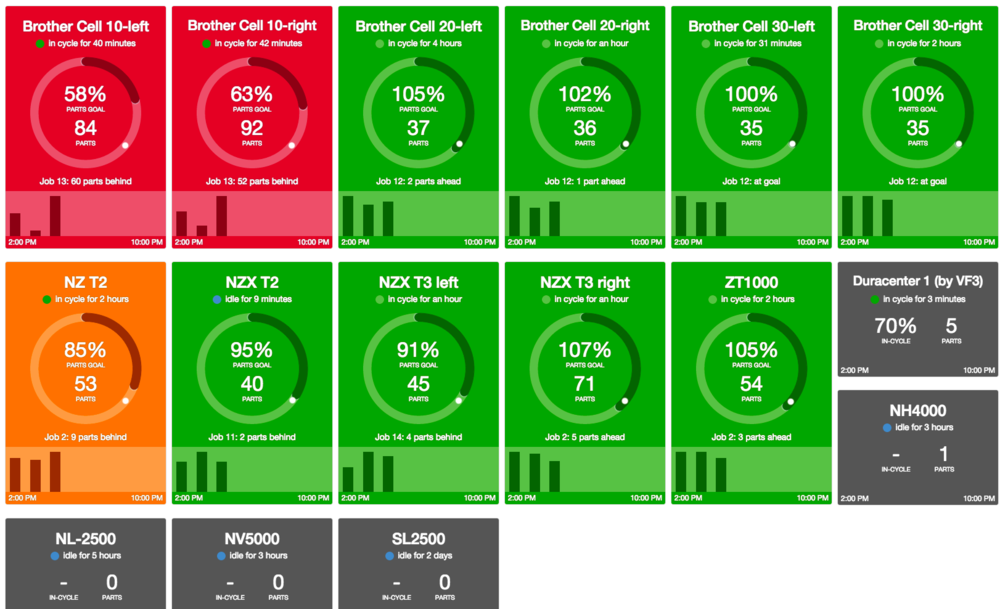

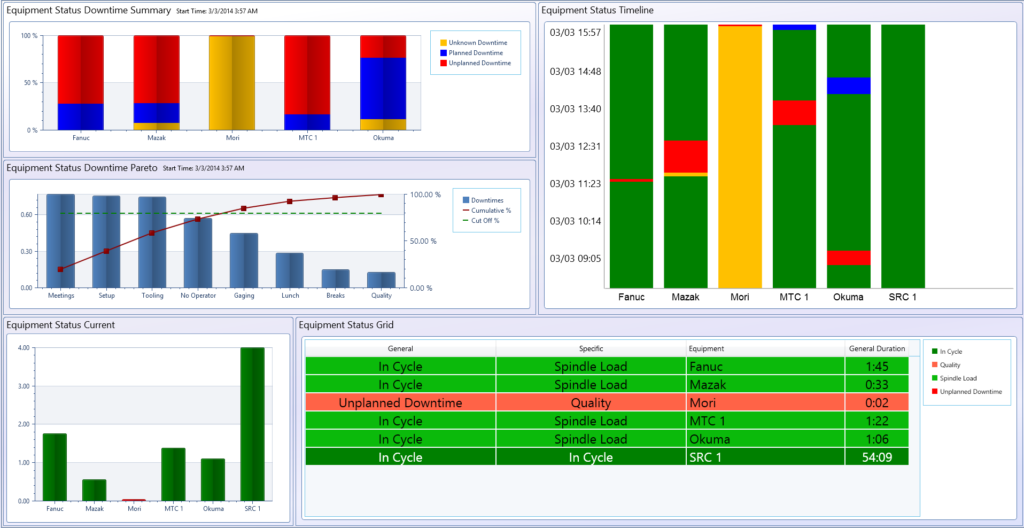

They can then configure a different view displaying an oee dashboard for shop floor managers. But the usefulness of these dashboards depends on the relevance of the data they present and whether that information eventually becomes meaningful actions. So you equip yourself with valuable insights into your manufacturing data from the shop floor to the back office. For example you can configure a dashboard for machine operators that displays specific machine data summaries.

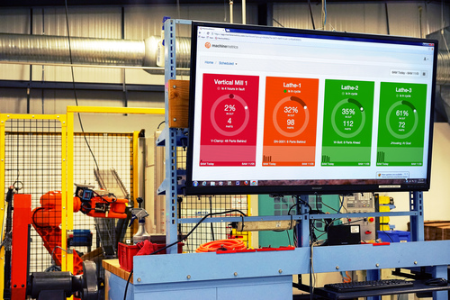

Let s take a look at some of the factors impacting performance along with examples of the types of dashboards and visual data that can helps. From customer to cash with exenta shopfloor. Shop floor dashboards provide real time data visibility integreater s data driven dashboard tool provides real time visibility to monitor and understand process specific performance. Shop dashboard v3 0 requires lojic dashboards to utilize security and author roles and template designer features testimonials works beautifully on a 65 size tv used mostly so machinists can glance up and see the next two upcoming jobs and stage the materials.

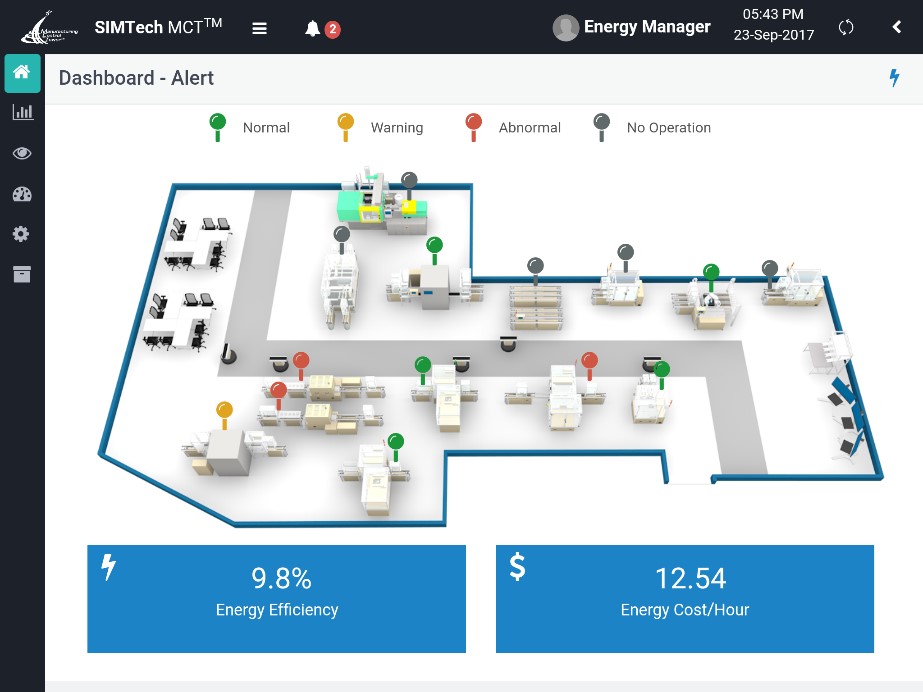

Increase shop floor productivity by fostering a healthy competition through leaderboards. The amount of time in a normal cycle status in a downtime or low feed rate overrides. They begin with a schematic or a floor plan and overlay critical product data and layer information about cell machine or plant performance on top. Receive incoming purchase order materials.

Create customized real time dashboards with data from your jobboss erp and other shop management applications too. Its flexible design means that it can be configured to measure whatever data is most important to each department. The basic idea is that the data empowers workers to identify issues and solve problems as they occur on the shop floor. When you re giving people key performance indicators kpis to track.

A visual shop floor presents performance indicators on production lines displays safety ratings monitors shipping and more and this visibility empowers workers and drives changes in behavior. Print work orders and release them to the floor. Boost accountability among your team through transparent performance metrics. Production qa financials you name it.

Always know where your work is when it will be complete and if you will meet your deadlines.