Shop Floor Control Goods Production

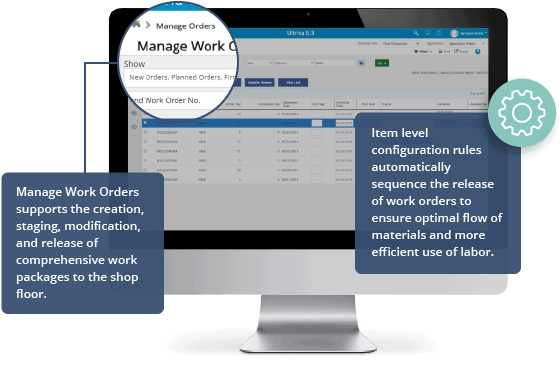

It allows you to manage and track manufacturing work orders processes and rate schedules.

Shop floor control goods production. Click here to leave comments suggestions about this website sap pp pppi home page sap shop floor control page goods issue to production order or process order so as to produce a production order quantity or a process order quantity you need to issue components in a quantity proposed in the order component list or as proposed in the. After this finished material is updated in quality stock. Learn more online today at exenta. Click here to leave comments suggestions about this website sap pp pppi home page sap shop floor control page.

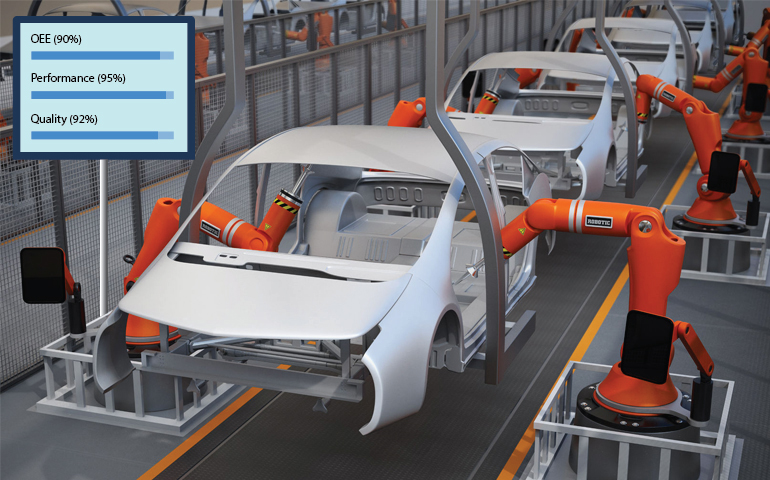

It includes the procedures to evaluate current resource status labor machine usage and other information required to support the overall planning scheduling and costing systems related to shop floor operation. Sap pp pppi goods receipts. Our real time mes eliminates the need for proprietary hardware while improving up to the minute production visibility and control. Goods receipts of finished material from rework order.

It is used to identify items that a shop floor person has tagged for removal from the work area. Discover elevated shop floor control systems for your apparel company with exenta. It is the list of goods and material a shop floor holds for repair resale manufacturing assembling or processing for a length of time. An effectively managed shop floor control system serves as a mediator between production control and the shop floor.

This material is posted into stock against production order. Goods issue to production order and completion of confirmation of production order same as explain above. It is a communication tool in the form of red colored paper tags. The shop floor is responsible to produce an intermediate or a final product.

Shop floor control comprises the methods and systems to prioritize track and report against production orders and schedules. Sap pp pppi goods receipts from order. After confirmation of all operations header material produced. When you produce something against an sap order production order or a process order you would first confirm the operations or phases or confirm the whole order and then bring to stock quantities.

Easy access path logistics production shop floor control goods movements goods receipts. Easy access path logistics production shop floor control.