Sap Capacity Planning In Shop Floor Control

Pp pi is an integrated standard solution for logistics tasks in the process industry.

Sap capacity planning in shop floor control. A quantity split or a standard value split. Step 1 from sap easy access screen open transaction cm21. Capacity leveling is done through planning table and you need to dispatch the orders to the work center in the sequence in which they are supposed to be processed at shop floor. In the below screenshot you can see that sap has offered many transactions in the capacity planning module.

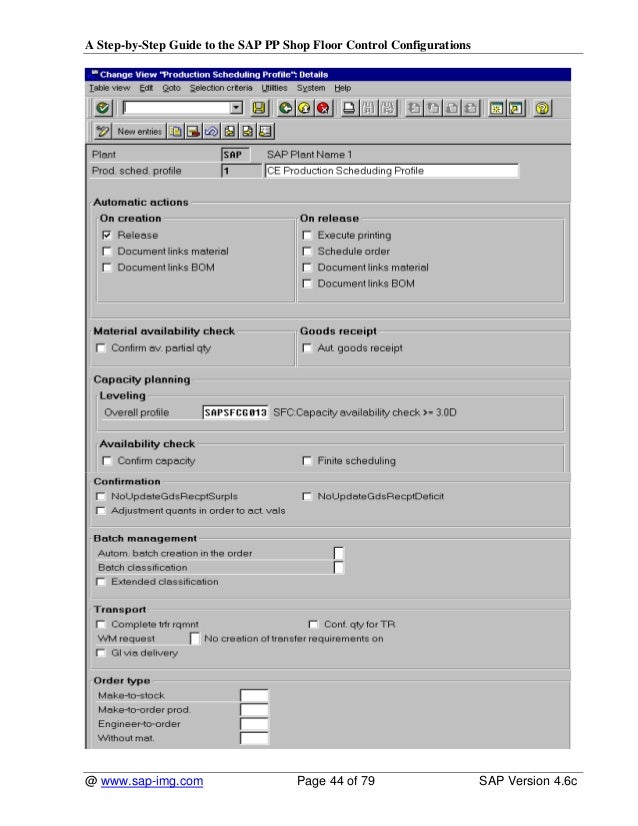

Shop floor control converts the planning data in material requirements planning into actual production orders and coordinates the production process with all the resources involved. The production order generates capacity requirements at the detailed planning level and these are. There is a detailed description of capacity leveling in shop floor control in capacity planning in shop floor control. Capacity planning in shop floor control.

Hi guys i am going on work shop floor control capacity planning shop papers and variant configuration. Long term planning pp ltp shop floor control pp sfc repetitive manufacturing pp rem process industries pp pi plant maintenance pm and customer service cs project system ps capacity planning can be flexibly adjusted to planning demands and to the area of responsibility within the company. Could some one explain me the relation between shop floor control capacity planning shop papers with workcenter routing and rem profile. Capacity planning is integrated in the following applications.

The main tool for carrying out production is the production order. Sales and distribution sd production planning and control pp sales operations planning pp sop requirements planning master production scheduling and material requirements planning pp mrp mps long term planning pp ltp shop floor control pp sfc repetitive manufacturing. Each transaction code is designed for a specific use case for example cm01 is designed to evaluate load at work center while cm21 is for leveling capacity requirements. Two types of split are possible.

How to do capacity levelling. Shop floor control converts the planning data in material requirements planning into actual production orders and coordinates the production process with all the resources involved. In the production order on the operation detail screen splitting you can split the total requirements of the operation into partial requirements so called splits. The shop floor control sfc is concerned with the detailed management of activities and the flow of materials inside the plant including the workers materials machines and time utilized in production.

Splitting capacity requirements in production orders.